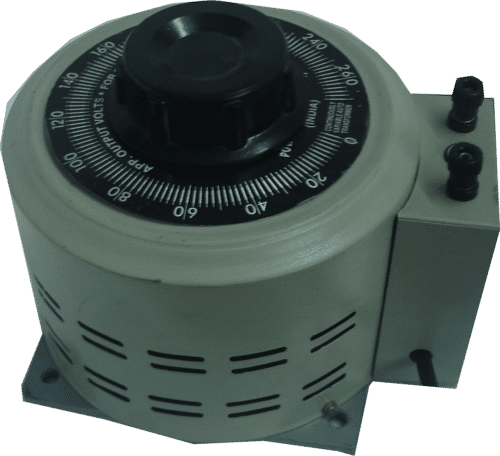

SINGLE PHASE VARIABLE AUTO TRANSFORMER 0-270V 8A

Price 5775 INR/ Piece

SINGLE PHASE VARIABLE AUTO TRANSFORMER 0-270V 8A Specification

- Low Voltage

- 0-470 V AC Volt (V)

- Coil Material

- Copper Core

- Material

- MS

- Output

- 0 - 270V AC

- Phase

- Single Phase

- Usage

- Industrial

SINGLE PHASE VARIABLE AUTO TRANSFORMER 0-270V 8A Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- All India

About SINGLE PHASE VARIABLE AUTO TRANSFORMER 0-270V 8A

"CROWNï offer good quality of single phase and three phase Auto Transformer. It has a single winding which is made up of supreme grade copper wire. the output voltage can be varied the as required.

SPECIFICATION

SINGLE PHASE AUTO TRANSFORMER

INPUT : 240V AC

OUTPUT : 0 - 270V AC

OUTPUT CURRENT (MAX.) : 8 Amp.

(ANY OTHER RANGE ALSO AVAILABLE AS PER CUSTOMER SPECIFICATION)

Precision Voltage Control

This transformer allows fine-tuned voltage adjustment from 0 to 270V AC, ensuring stable power for sensitive industrial equipment. The copper coil ensures high conductivity and minimal energy loss, enhancing reliability in demanding settings such as testing and automation.

Durable Construction & Industrial Utility

Crafted with a sturdy MS enclosure and a copper core coil, the auto transformer guarantees longevity and optimal heat dissipation. Widely used by manufacturers, exporters, and traders in India, it suits a broad spectrum of industrial applications, from factory machinery to quality control labs.

FAQs of SINGLE PHASE VARIABLE AUTO TRANSFORMER 0-270V 8A:

Q: How does a single phase variable auto transformer operate?

A: A single phase variable auto transformer works by allowing the user to manually adjust the output voltage from 0 up to 270V AC. This is achieved through a rotating dial connected to the copper wound coil, enabling precise voltage control for different industrial requirements.Q: What benefits does this transformer offer to industrial users?

A: This transformer provides smooth, step-less voltage adjustment, reducing equipment wear and improving testing accuracy. Its copper core ensures efficient power transmission, while the rugged MS body enhances durability and safety in tough industrial environments.Q: Where can this variable auto transformer be used?

A: Primarily intended for industrial use, the transformer is suitable for applications requiring controlled voltage, such as machinery testing, calibration labs, quality assurance work, and automation systems across various manufacturing and R&D sectors.Q: What is the process for integrating the transformer into an industrial setup?

A: Integration involves securely wiring the transformer into the main supply, ensuring correct phase alignment, and grounding as per standard safety protocols. The output can then be connected to the equipment requiring variable voltage supply, with adjustments made using the control dial.Q: When is it advisable to use a variable auto transformer instead of a fixed output model?

A: Variable auto transformers are ideal when different voltage levels are needed for testing, research, or operational processes. They are preferable to fixed models in environments where equipment requires varying input voltages or where precise voltage regulation is crucial.Q: What materials are used to ensure longevity and performance?

A: The transformer is constructed with copper for the coil, offering superior conductivity and reduced power loss, while the main enclosure is made from MS (mild steel) for robustness and enhanced protection in industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AUTO TRANSFORMER (VARIAC) Category

SINGLE PHASE VARIABLE AUTO TRANSFORMER 0-270V 4A

Price 4500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : MS

Phase : Single Phase

Usage : Industrial

Output : 0 270V AC

THREE PHASE VARIABLE AUTO TRANSFORMER 0-470V 28A

Price 63500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : MS

Phase : Single Phase

Usage : Industrial

Output : 110 V

SINGLE PHASE VARIABLE AUTO TRANSFORMER 0-270V 6A

Price 5200 INR / Piece

Minimum Order Quantity : 1 Piece

Material : MS

Phase : Single Phase

Usage : Industrial

Output : 0 270V AC

THREE PHASE VARIABLE AUTO TRANSFORMER 0-470V 2A

Price 10500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : MS

Phase : Three Phase

Usage : Industrial

Output : 0 470V AC

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS